21

COROMANDEL LIFE

SUMMER 2014

I

got into beekeeping quite by accident while

in the process of developing a lifestyle block

and installing an organic, heritage fruit and

nut orchard in the permaculture model of

sustainable agriculture.

Bees were a natural part of this and quickly

developed into a passion, diverting my career

into commercial organic beekeeping.

The thing I love most about beekeeping is the

integrative nature between beekeeper and

hive. A symbiotic alignment of mutuality exists

in a relationship of unspoken connection.

In my experience bees express through a

group consciousness. Individuality as such

does not exist and behaviour is collectively

intuited solely for the benefit, enhancement

and survival of the hive.

As a beekeeper, I am an integral member of

each individual hive as well as the greater

collective of the hives under my care. My

responsibility is to nurture and maintain the

bee’s quality of life, honouring that integrative

bond between beekeeper and bee.

We are ‘family’ ... My role is to ensure the

health and harmony of the bees and provide

for them as they provide for me.

This Kiwi-manufactured Boutelje 24FS Manuka Honey extractor is capable

of extracting manuka and all other honey. The bee’s wooden frames are

placed vertically, and the drum spins, forcing the honey from the combs

to drain at bottom. Another Boutelje centrifuge helps reclaim all wax and

honey. It separates the slurry of comb/capping wax and honey; the lighter

weight wax is spun to its own layer, then scraped off.

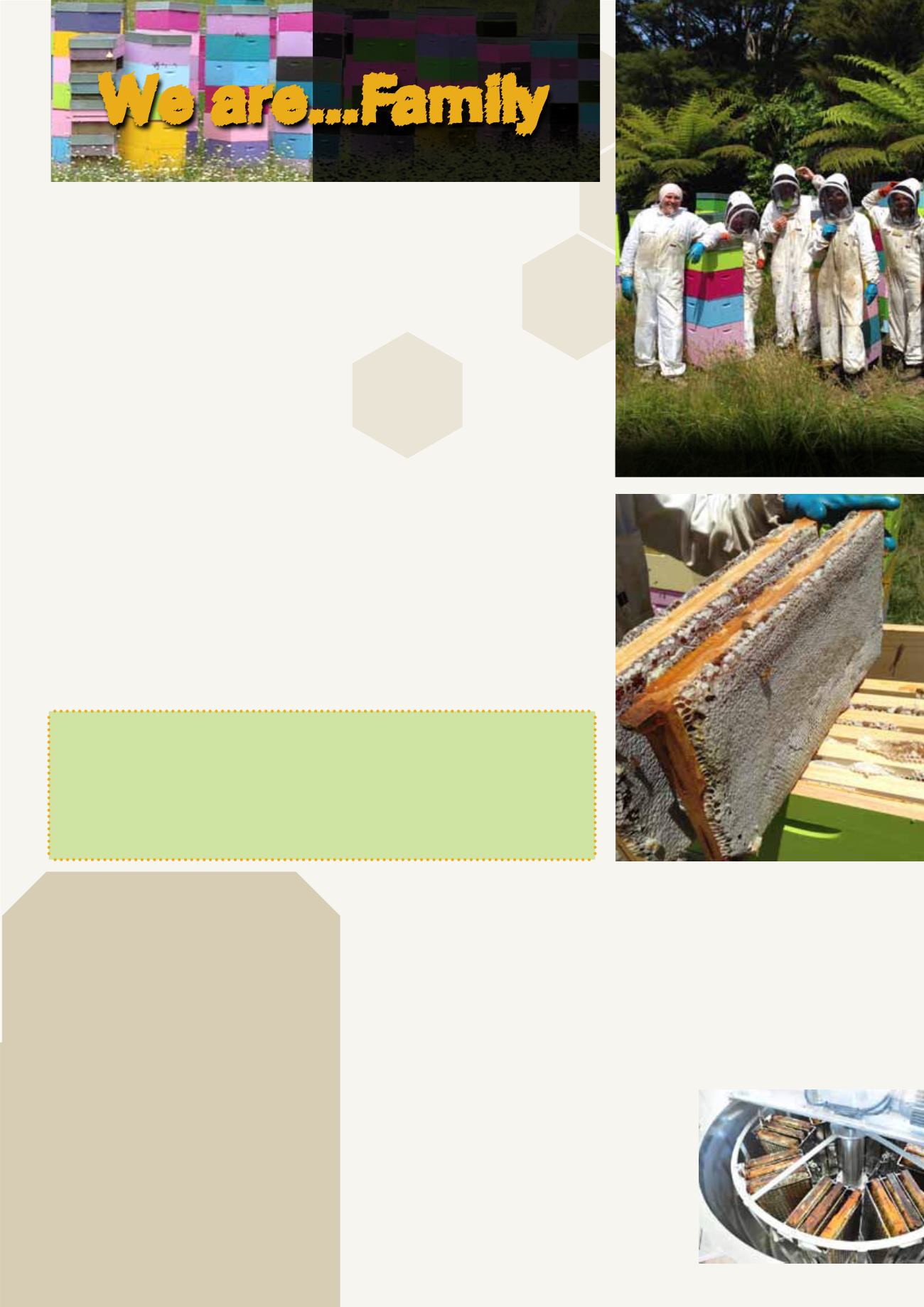

The Sanctuary Honey

team and their bees

“

Sanctuary Honey

is one of only a few Organic Manuka producers in New Zealand,” says Paul Berry. They

produce and export Certified Organic Active Manuka honey, wax, propolis and STING, the world’s only Active

Manuka honey mead.

“We also source and supply all NZ-produced organic/non-organic honey types, around 25 different lines, from

native bush honey blends to high activity 20+ UMF Manuka.”

Sanctury is more export focused, both their own honey and from other beekeepers. “We pack under two brands

in-house for export. We provide storage and sale for bulk and retail honey packed under your label or ours.” If you

are a commercial beekeeper, contact Paul for assistance in meeting your export requirements. Ph 021-467756

My concern about the beekeeping industry

worldwide is the attitude of dissociation

of beekeepers to their bees. Where no

compassion exists and bees are viewed as

an ‘expendable commodity’ to be used,

abused and discarded in the endless cycle of

intensive pollination.

Intensive monocultural pollination practices

– where bees are force fed genetically

modified corn syrups, forced to eat low

nutrient chemically contaminated pollens, and

endure high stress levels from hives being

continually moved – is in my opionion the

primary contributing factor in the declining bee

population worldwide.

Yes, conditions are idyllic in NZ due to the

unique nature of the native bush composition

that provides the unique and most prolific

natural endemic nectar sources in the world.

The monoculture of incessant bee pollination

is indeed akin to ‘bee slavery’ and an affliction

on this beautiful creature showing greed and

unsustainable farming practices.

Sanctuary Honey’s land is located in a secluded valley in

Whenaukite. Paul and partner Angela are creating a retreat

centre based on organic/permaculture principles.

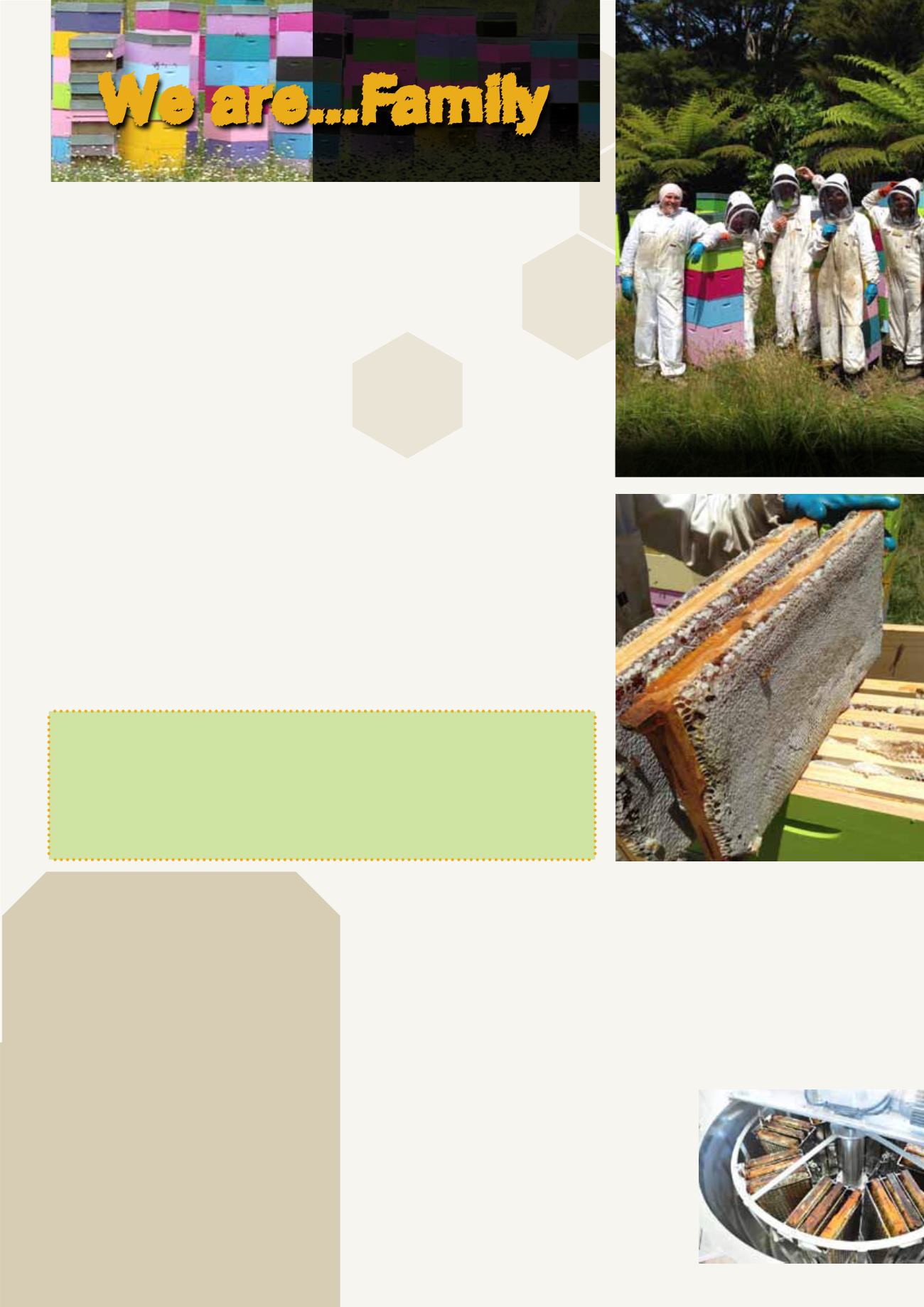

T

he extraction process separates the liquid honey from the sealed waxy comb the bees

produced to protect their golden food.

After gathering the honey laden hives from the fields, beekeepers return to their ‘honey shed’.

First, the honey frames are rested in a heated room for a few days to soften the wax and

honey. Then the wax caps are sliced off with either a hot knife or with an automated uncapper.

The uncapped frames are placed in an extractor which resembles a stainless steel top loader

washing machine. When the combs are positioned correctly and the machine is turned on, the

honey is spun off by centrifugal force. The honey is collected at the bottom of the barrel and

put through varying degrees of heating and/or filtering.

Nothing is wasted, and the waxcomb caps and residue

will be processed to extract further honey and reclaim

wax. Once the barrels of honey are filled, they are ready

to be jarred or packed, much of it for export.

EXTRACTING

THE

GOLD

About the hive layers:

A series of inside boxes are

suspended on frames on which honeycomb is built. The

bottom box, or ‘brood box’, is where the queen is housed

and lays her eggs.

Above this the ‘supers’ or ‘honey supers’ have more frames

hanging inside, and it is here the workers make the comb

and fill it with honey. The large queen is restricted from this

area with a ‘queen excluder’ – a metal grille with thin bars

close enough to prevent her from getting through but wide

enough for the smaller workers and drones to pass. This

way no eggs are laid in the cells and beekeepers are able to

remove frames that are filled entirely with honey. The hive is

weather-proofed with a wooden or metal lid.

LANGSTROTH HIVE BOX

REVOLUTIONISES BEEKEEPING

ON THE COROMANDEL

The first bees came to NZ in 1839. Just 13 years

later a boom in the honey industry was taking

place when American Lorenzo Lorraine Langstroth

patented the Langstroth Hive in 1852. In 1880

the famous boxes were brought to NZ and the

Coromandel was one of the first areas to adopt

them. They are still commonly used among

beekeepers today. (dtagram at left)

We are

...

Family

nurture ... maintain ... honour

by Paul Berry of

Sanctuary Honey

Paul Berry and crew tend to their hives out

in the field. Below two frames with combs

ready for honey harvest.