W

hen hives are full and ready to be

harvested, Hayward beekeepers arrive

on site. Using blowers and smoke,

they remove most of the bees from a hive’s

upper boxes, the ‘supers,’ which are taken to the

processing shed for harvesting. The bottom box

or ‘deep super,’ which holds the queen and her

brood, is left behind and the bees get back to

work while the keeper moves on to the next hive.

Harvesting time follows the completion of

a particular flowers’ bloom. This year, the

rewarewa bloomed exceptionally well before

Christmas, providing the beekeepers with two

harvesting periods: one for the rewarewa, and

the other at the end of the summer for manuka

and bush blends.

Back at the shed, boxes are stacked according

to the collection areas to ensure the manuka

batches don’t get mixed with the clover blend,

for example.

OPERATION HONEY

The honey shed is a unique working

environment. From the outside it just looks

like an old shed, the exception being the

hundreds of hovering bees who have made

the trip with the hives. But inside it’s another

world, the dimly lit storage shed (called the ‘box

shed’) holds towers of stacked, pastel painted

boxes. It’s an impressive sight that is slightly

intimidating, given the bee to human ratio is

1000:1, and yet there’s a calming atmosphere.

Some bees gather toward a window in the

ceiling, the rays of light beam through, giving it

a virtuous glow.

Another hive storage area contains an isolated

window that is also covered in bees. This

solitary source of light in the room creates an

illuminated pathway that attracts them. As we

move around the supers, I’m quickly instructed

to avoid this ‘buzzway’ and the hundreds of

bees moving along it toward the light. This ‘light

lure’ makes it easier to see and avoid them.

One of the beekeepers occasionally opens the

window to release them from the shed and

back to nature.

As the walking tour through the shed continues,

owner Bonk Hayward’s extensive knowledge of

bees is revealed. I find myself trying to digest

all this new information while keeping my cool

as bees buzz around me, some even landing on

my shoulder. Believe it or not, I made it through

unscathed... and unstung!

There are many jars of honey in various colours

and shades on the shelves. Bonk tells me these

have been saved from the past three seasons

for traceability and testing purposes. For him,

distinguishing the type of honey is second

nature. He points and reaches for this season’s

rewarewa jar. “Just by looking at it you can

tell... see how runny and dark it is? That’s what

makes Coromandel honey different: it’s well

known for being darker which means more

intense flavours.”

What about the famous manuka? Bonk

explains the region produces many honeys

worth raving about, but their bush blend

manuka is not among the power hitters in

the ratings. (Some Coromandel producers

specialise in potent active manuka, but

generally, the manuka honey certified and

top rated for bioactivity originates from the

East Cape region around Gisbourne, the

easternmost tip of North Island, stretching from

Maihia in the south to Opotiki in the north.)

Bonk then opens up a sliding door, taking us

into the processing room where we are greeted

by the rich smell of honey, an intense humming

of machinery and a blasting radio. Here the

beekeepers pull frames from the boxes and

guide them through the uncapping machine to

remove the beeswax seal over each cell. In an

8 hour shift the busy crew will get through 6-7

pallets of supers. And no beesuits needed for

for these keepers; the guys are comfortable

without them in the shed.

UNCAPPED AND READY TO SPIN

The room has a warm temperature allowing

the honey to flow easily through the machines

and pumps. Interested in how the honey is

processed? We’ve broken it down for you:

Stage One: Uncapping

Each super is made up of ten frames. Each frame

is fed through the honey capper which slices the

wax off each face of the frame. The scraped wax

is collected at the base of the machine. Patches

of wax missed by the capper are sheared with a

shearing comb – an extremely appropriate name!

At the end of the machine, the caps are further

punctured so every cell is opened up and ready

to be extracted in the mighty centrifuge.

Stage Two: Centrifuge Extractor

The uncapped frames are dripping with luscious

honey now that the protective layer of wax has

been removed. The frames are placed into a top

loader washing machine doppelganger. They are

put on a cycle of 9 minutes – 3 minutes forward,

3 minutes backwards and another 3 minutes

forward.

(

See next page for photo).

These cycles

vary with the type of blend being processed.

Monofloral or clover blends are processed for 6

minutes all up. The honey is collected at the base

of the extractor and pumped through to the next

machine for further refinement.

Stage Three: Capping spinner

Further spins the honey, separating more wax.

This machine also resembles a stainless steel

washing machine. A giant sieve bucket captures

the wax and lets the honey further filter out into a

separate pump which transports it to the ‘waffle’

machine. The collected wax is pumped through to

the cork screw machine…

Stage Four: Cork screw

The cork screw condenses the wax which is then

taken to the wax room.

Stage Five: Waffle tank

The waffle tank, the last filtering machine,

removes the remaining traces of wax as the

honey moves through a baffle or strainer system.

The wax and residue float to the top and are

cleaned out each night. The waffle tank is warmed

slightly to 35 degrees to ease the flow of honey

through the filters. It isn’t heated any higher as

temperatures over 60 degrees will pasteurise the

honey and destroy some of its healing power –

further filtering the nutrients out of the honey.

by Claire Fitzjames

The last two issues offered a glimpse into the life

of bees and their keepers, including Haywards

Honey Shop. They are the largest apiary on the

Coromandel and export all they produce. Their

main office is in Tairua, but ‘bee business’ is either

out in the field or on the farm in Whenuakite where

their honey processing buildings are located.

Hayward Honey Shop invited us to see how

honey makes its way from the hive to the jars

on the shelf. Keep reading for an insight into the

fascinating harvesting and extracting process and

the many ways you can enjoy your honey.

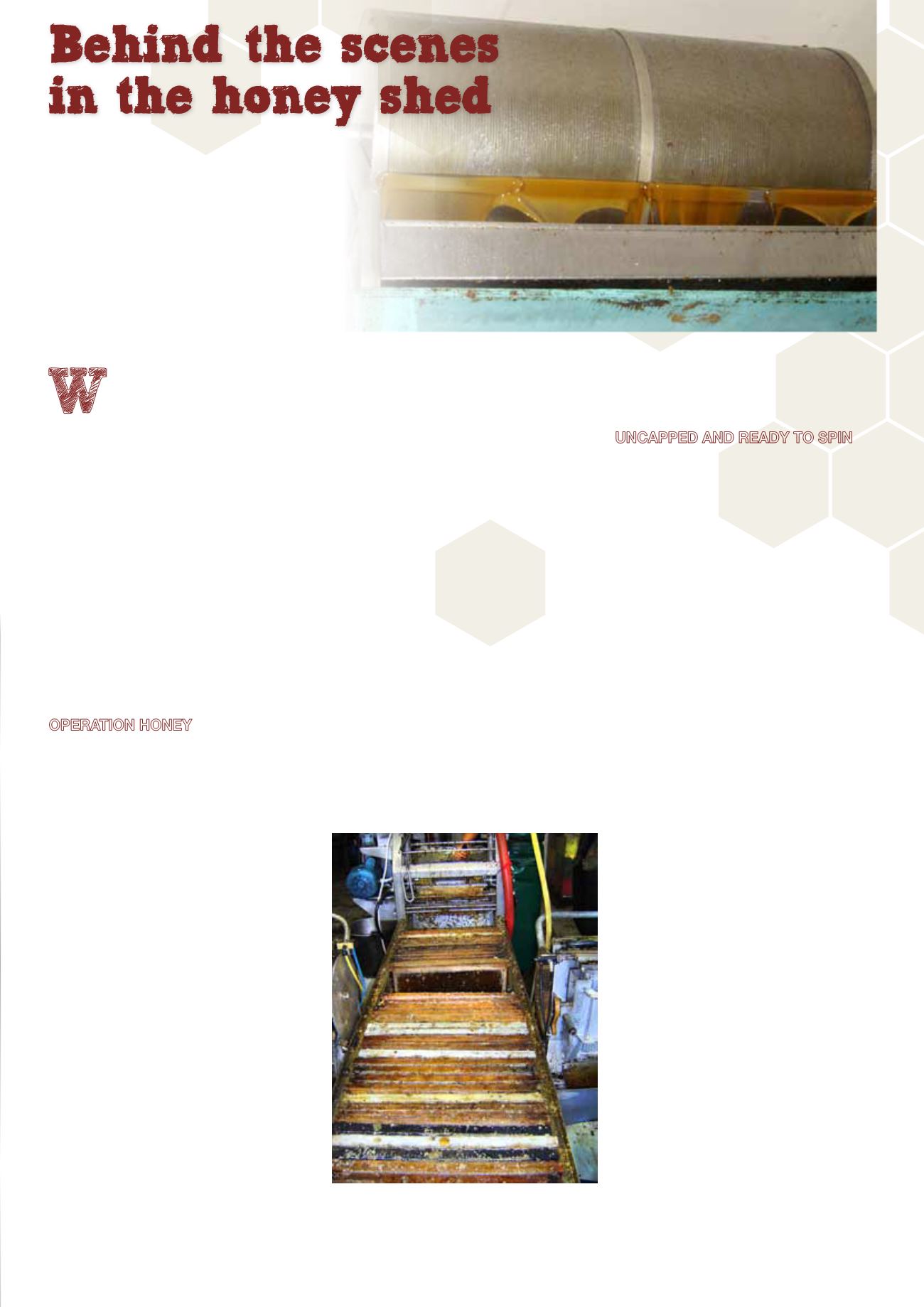

Honey comb laden frames line up to go through

the uncapping machine. The wax is sliced off, then

the cells of the comb are pricked so the honey is

ready to be spun out in the centrifuge extractor.

Another process reclaims the beeswax.

Behind the scenes

in the honey shed

43